Page 5. Corrosion and Archaeology

Corrosion

is one of the greatest enemies of archaeological finds and findings. All kinds

of materials are its victims: metals, glass, ceramics, mortars, stuccos, paper,

leather, textiles, pigments, dyes etc.

The kinds

of reactions causing corrosion are as numerous as the kinds of materials.

Water,

liquid or vaporous, is the mother of the overwhelming majority of corrosion

processes, supported by oxygen, carbon dioxide and other atmosperiles.

Corrosion by radiation (electromagnetic or particles) can work without water,

but humidity intensifies the attack. Carbonizing is the process of dehydration

(withdrawal of water) of cellulose.

Two special

cases of corrosion will be treated here, the electrochemical corrosion of

metals and the chemical corrosion of glass.

The Electrochemical Corrosion of Metals

The Electrochemical Corrosion of Metals

The

electrochemical corrosion of metals is due to the formation of local galvanic

cells. The resulting electric current leads to the dissolution of the anode and

the deposition of ions on the cathode. Such galvanic cells can be formed by one

piece of metal which has two zones of different metal concentrations,

surrounded by an electrolyte, an aqueous solution. This sounds to be strange,

but the concentration of metal atoms in a piece of metal can be changed locally

by extreme pressure, as e. g. caused by hammering. Since hammering is a

frequent way of forming metal objects, this kind of corrosion happens often to

metallic archaeological finds, not only of iron, but also of bronze and other

metals. This effect makes metal plates look irregularly penetrated and if it

were eaten away.

P. C. Bol mentions briefly this phenomenon in his book

Antike Bronzetechnik – Kunst und Handwerk antiker Erzbildner, Verlag Beck

Muenchen (1985) pp. 18; 82.

|

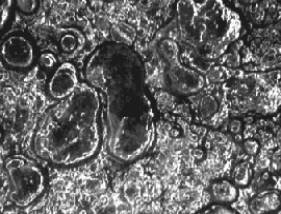

The photo

shows a beaten bronze ornamental mounting of a celtic wooden box. The typical

corrosion character can be seen. (with

kind permission of Historisches Museum Basel, CH) |

|

An instructive

experiment is outlined here which can illustrate this effect.

An iron

nail is produced by cutting off a piece of wire and forming the head and the

point by compressing and sharpening its ends, respectively, at room

temperature. Due to the extreme mechanical stress in cold condition the crystal

lattice in these zones is condensed, the concentration of iron atoms locally

increased. This leads – together with a certain roughening of the surface - to

a higher tendency to dissolve here than in zones which have not been deformed.

When immersed in an electrolyte, head and point of the nail are the anodes, the

shank is the cathode of the galvanic concentration cell formed.

The

dissolved iron, present as iron ions, can be detected by a suitable reagent. In

this case potassium hexacyanoferrate(II) has been chosen, which reacts with

iron ions to a blue compound, called Berlin Blue.

|

|

Corrosion

of an iron nail at zones compressed during production Length of

nail 80 mm. (Foto:

Author) |

The picture

given here shows a nail embedded in a gelatine gel containing a low

concentration of the reagent. You see the blue spots around head and point, indicating

that the nail starts here to dissolve. The third blue zone developed at a

little damage of the shank which caused a compression and/or damage of the

crystal lattice also here.

This

picture illustrates that compressed zones, e. g. caused by beating or

hammering, corrode easier than not compressed zones. Generally, beaten objects

corrode easier than cast objects. But be carefull: The type of alloy, the wall

thickness and the roughness of the object also play a role. Their influence

will add to the electrochemical effect.

The Chemical Corrosion of Glass

The Chemical Corrosion of Glass

Glass is

not as resistant against attacks of corrosive media as one may think. Even

water leads to corrosion by dissolving the alkalimetal ions, preferred

potassium. Acid and alkaline substances intensify corrosion.

Antique or

medieval glass is not a homogenious material but consists of two or more

different phases (kinds of glass), which are more or less soluble in one

another. They exist side by side, mostly in form of bubbles of one phase in a

surrounding matrix of the other phase. These different kinds of glass have

different corrosion properties, one corrodes more easily than another one. This

leads to a characteristic corrosion phenomenon which is shown in the following

picture.

|

Corroded

surface of a medieval potassium glass fragment. The photo shows deepenings

formed by complete dissolution of the more soluble potassium glass phase in

the more resistant matrix. The structures are flattened by the blowing

process. (Surface microscope, magnified 15 times. The deepenings can be seen

with the naked eye). |

|

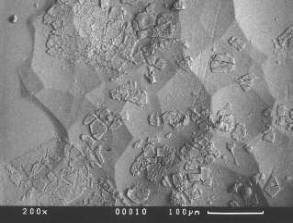

The next

photo shows the ongoing corrosion process by formation of little tiles. In a more

developed condition these tiles can be seen with the naked eye as little

silvery plates, looking like mica.

|

Corrosion

process in progress by formation of little tiles flaking off. (Scanning

electron microscope, magnified 200 times). |

|

The

relatively low corrosion resistance of potassium glass (wood-ashes glass) is

responsible for the bad condition of many medieval coloured church windows.

By the way:

also the corrosion of ceramics starts with the dissolution of potassium ions.

Literature: P. Kurzmann, Mittelalterliche Glastechnologie

(2004).